Precision collision repair facilities differentiate themselves through stringent standards requiring advanced knowledge of automotive manufacturing and materials. They specialize in complex damage scenarios, employing advanced equipment and trained professionals for services like frame straightening, panel replacement, and paint matching to restore vehicles to pre-accident condition. Quality control, including meticulous inspections and visual examinations by experienced technicians, ensures repairs meet original specifications, enhancing customer satisfaction and maintaining the integrity of their work. Consistent practices focusing on panel alignment and paint job perfection, coupled with comprehensive documentation and regular training, solidify these shops as reliable authorities in precision collision repair.

In the realm of precision collision repair, maintaining high standards is paramount to ensure vehicles return to their pre-accident condition. This article delves into the essential quality control (QC) procedures vital for professional repair facilities. We explore how adhering to precision collision repair standards and implementing robust QC measures fosters consistency, enhances customer satisfaction, and stands as a testament to the facility’s expertise. By understanding these key procedures, shops can elevate their reputation in the competitive automotive market.

- Understanding Precision Collision Repair Standards

- Key Quality Control Procedures for Effective Implementation

- Ensuring Consistency and Customer Satisfaction Through QC Measures

Understanding Precision Collision Repair Standards

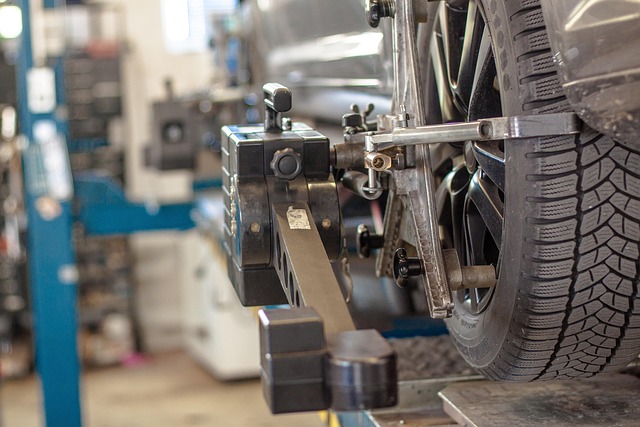

Precision collision repair facilities adhere to stringent standards that differentiate them from regular auto body shops. These standards require a deep understanding of automotive manufacturing processes and materials, ensuring that repairs are both structural and aesthetic. The goal is to maintain the vehicle’s original design integrity and safety features, making precision collision repair a specialized service for complex vehicle damage scenarios.

Collision repair centers specializing in precision repair offer advanced auto body services, employing state-of-the-art equipment and trained professionals. Auto maintenance at these facilities involves meticulous attention to detail, from frame straightening and panel replacement to paint matching and finish perfection. This level of expertise is crucial for restoring vehicles to their pre-accident condition, ensuring both customer satisfaction and vehicle safety.

Key Quality Control Procedures for Effective Implementation

In the realm of precision collision repair, effective quality control procedures are paramount to ensuring top-notch vehicle bodywork restoration. Key practices involve meticulous inspection and measurement using specialized tools to verify repairs align with original manufacturing specifications. Trained technicians play a crucial role in this process by conducting visual examinations, performing dynamic tests, and comparing results against industry standards.

Implementing these quality control measures not only guarantees the integrity of the car body shop’s work but also enhances customer satisfaction. By adhering to rigorous procedures, vehicle repair services can maintain their reputation for excellence, ensuring each restored vehicle meets or exceeds expectations in terms of aesthetics, functionality, and overall performance.

Ensuring Consistency and Customer Satisfaction Through QC Measures

In the realm of precision collision repair, maintaining consistency is paramount to customer satisfaction and ensuring every vehicle leaves the collision repair shop in top condition. Quality control (QC) measures serve as the cornerstone of this process, meticulously scrutinizing every aspect of the repair work. From panel alignment to paint job perfection, QC procedures guarantee that each step adheres to the highest standards. By implementing rigorous testing and inspection protocols, collision repair centers can deliver consistent, reliable results, fostering trust among their clientele.

Consistency is key to building a reputation for excellence in the collision repair industry. Customers expect their vehicles to be restored to pre-accident condition, if not beyond. Through comprehensive QC practices, including detailed documentation and regular training sessions, collision repair shops can offer tire services that meet or exceed industry benchmarks. This commitment to quality not only ensures customer satisfaction but also positions the collision repair center as a reliable, trusted authority in precision collision repair.

Precision collision repair facilities that implement robust quality control (QC) procedures are not only ensuring the highest standards of work but also fostering customer satisfaction and reputation. By understanding the nuances of precision collision repair standards and adopting key QC measures, these facilities can maintain consistency in their services, leading to long-lasting relationships with clients and a competitive edge in the market. This commitment to quality is paramount in the automotive industry, where trust and accuracy are paramount.