Precision collision repair revolutionizes the automotive industry by restoring vehicles to original specifications using advanced technology and skilled technicians. This method is beneficial for fleet services and various types of damage, from minor dents to complex structural issues. State-of-the-art equipment ensures flawless alignment, preserving aesthetics and safety. The process involves comprehensive inspections, metal realignment, and expert panel replacement with OEM parts, resulting in seamless fitment across bodywork.

In today’s automotive landscape, precision collision repair is paramount for maintaining vehicle safety and aesthetics. This advanced approach ensures that cars return to their original alignment and fitment standards after an accident. By employing specialized techniques and cutting-edge technology, technicians achieve exacting measurements and adjustments. From initial assessment to final restoration, each step guarantees a seamless blend with the vehicle’s pre-collision state. Discover how these methodologies revolutionize car repair, prioritizing both functionality and visual perfection for every make and model.

- Understanding Precision Collision Repair Techniques

- The Role of Advanced Technology in Alignment

- Ensuring Optimal Fitment: A Step-by-Step Process

Understanding Precision Collision Repair Techniques

Precision collision repair techniques have revolutionized the automotive industry, ensuring that vehicles are restored to their original specifications after a crash. This advanced approach goes beyond basic vehicle fixing; it involves meticulous measurements, state-of-the-art equipment, and highly skilled technicians. By employing these techniques, auto collision centers can deliver impeccable results, whether handling minor dents or complex structural damage.

These methods not only align the vehicle’s components precisely but also maintain its original fitment, ensuring that every part functions optimally. Fleet repair services, for instance, benefit significantly from precision collision repair, allowing businesses to keep their vehicles on the road longer and reduce overall maintenance costs. Even in the case of a vehicle dent repair, precision techniques guarantee that the fix is both invisible and durable, maintaining the vehicle’s aesthetic appeal and safety.

The Role of Advanced Technology in Alignment

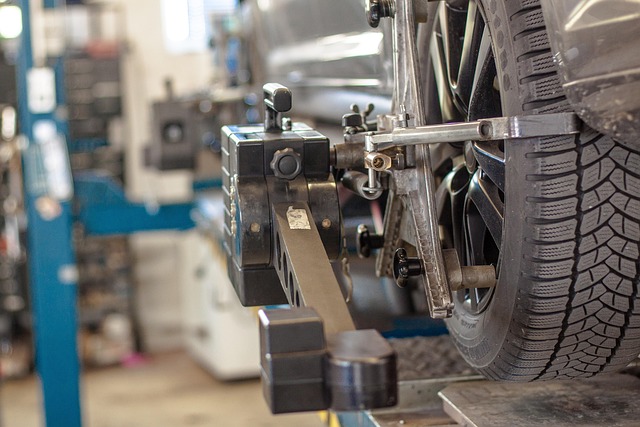

In the realm of precision collision repair, advanced technology plays a pivotal role in achieving flawless alignment and fitment. Modern tools like laser measurements and computer-aided design (CAD) software enable technicians to pinpoint exact dimensions and angles, ensuring every component is perfectly aligned after repairs or replacements. These technologies significantly enhance accuracy compared to traditional methods, resulting in superior structural integrity and aesthetic appeal.

For instance, in classic car restoration projects where attention to detail is paramount, precision collision repair techniques come into play. A Mercedes-Benz repair shop utilizing state-of-the-art equipment can meticulously calibrate body panels, suspension systems, and steering components, recreating the original factory specifications. This meticulous approach not only preserves the vehicle’s historical integrity but also guarantees optimal handling and safety, catering to both automotive enthusiasts and everyday drivers seeking top-tier tire services.

Ensuring Optimal Fitment: A Step-by-Step Process

Ensure Optimal Fitment: A Step-by-Step Process

Precision collision repair goes beyond simply fixing dents and dings; it involves meticulous attention to detail in order to achieve optimal fitment across every component of a vehicle’s bodywork. The process starts with a thorough inspection, where skilled technicians meticulously assess the damage, taking measurements and using advanced technology to pinpoint exact locations. This initial step is crucial as it lays the foundation for subsequent repairs, ensuring that every angle and curve aligns perfectly.

Next, frame straightening techniques are employed to realign any warped or bent metal structures. This may involve specialized equipment like hydraulic presses and robotic welders to carefully straighten the frame without compromising its structural integrity. Once the frame is correctly aligned, body shop services continue with precise replacement of damaged panels, utilizing original equipment manufacturer (OEM) parts whenever possible. Technicians employ techniques such as spot welding, panel beating, and expert paintwork to ensure that every detail matches the vehicle’s original specifications, resulting in seamless fitment across the entire vehicle bodywork.

Precision collision repair is not just about fixing cars; it’s about restoring them to their original, pre-collision excellence. By employing advanced technology and meticulous step-by-step processes, professionals ensure optimal fitment and perfect alignment. This level of detail ensures that every vehicle leaves the workshop as good as new, guaranteeing safety, performance, and peace of mind for the road ahead.