Precision collision repair prioritizes manufacturer specifications for both vehicle safety and aesthetic restoration. Advanced technology, including 3D scanning, robotic welding, and CAD software, aids in achieving exacting standards for body panel replacement, painting techniques, bumper repair, and frame straightening. This meticulous approach leverages skilled craftsmanship to deliver top-tier repairs that preserve the car's long-term value, maintain structural integrity, and provide customers with safe, reliable, and visually appealing vehicles.

Precision collision repair is a game-changer, ensuring vehicles return to their original manufacturer specifications after an accident. This meticulous process navigates a complex landscape where every detail matters. Manufacturers set stringent standards, and top-tier repair shops employ advanced technology to meet these specs. From 3D scanning to robotic welding, these tools enable technicians to restore vehicles with unparalleled accuracy, guaranteeing both quality and safety. Understanding and adhering to manufacturer guidelines is the cornerstone of exceptional precision collision repair.

- Understanding Manufacturer Specifications in Collision Repair

- The Role of Technology in Achieving Precision Collision Repair

- Ensuring Quality and Safety through Strict Adherence to Specs

Understanding Manufacturer Specifications in Collision Repair

In the realm of precision collision repair, adhering to manufacturer specifications is paramount. These specs are not just guidelines; they represent the exacting standards set by automotive manufacturers for every aspect of a vehicle’s construction and assembly. For instance, fender repair involves more than simply fixing a dent; it necessitates precise measurements, specific techniques, and materials that align perfectly with the original design. The same meticulous approach is required in every step of vehicle collision repair, from body panel replacement to painting.

Manufacturer specifications guide every detail, including color codes for paint matching, panel gaps, and even the type of adhesives used. This level of accuracy ensures that the repaired vehicle not only looks identical to its pre-collision state but also maintains optimal structural integrity. For professional collision repair services, these specs serve as the blueprint for restoring vehicles to their original condition, ensuring customer satisfaction and preserving the vehicle’s value in the long run.

The Role of Technology in Achieving Precision Collision Repair

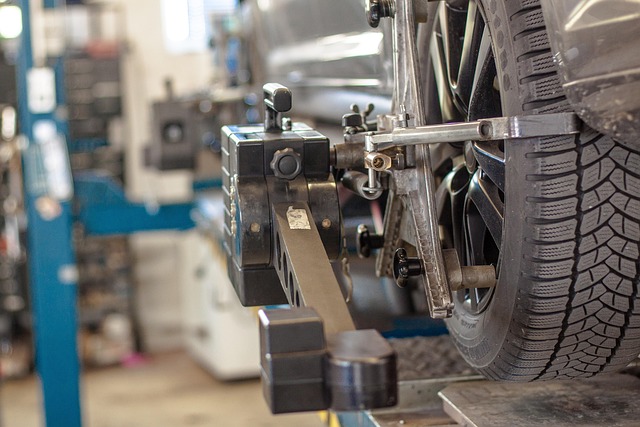

In the realm of precision collision repair, technology plays a pivotal role in achieving unparalleled accuracy and quality. Advanced tools and software have revolutionized car bodywork services, enabling auto detailing experts to navigate complex repairs with ease. 3D scanning, for instance, captures intricate vehicle details with meticulous precision, serving as a digital blueprint for precise restoration. This level of technological sophistication ensures that every curve, contour, and crevice is meticulously replicated, resulting in repairs that seamlessly blend with the manufacturer’s original specifications.

Furthermore, robotic welding systems and computer-aided design (CAD) software streamline the repair process, enhancing accuracy and consistency. These tools allow for precise measurements and adjustments, minimizing human error and maximizing structural integrity. By combining these technological advancements with skilled craftsmanship, automotive repair professionals can deliver top-tier results that meet and often exceed strict manufacturer specs, ultimately providing customers with safe, reliable, and aesthetically pleasing vehicles.

Ensuring Quality and Safety through Strict Adherence to Specs

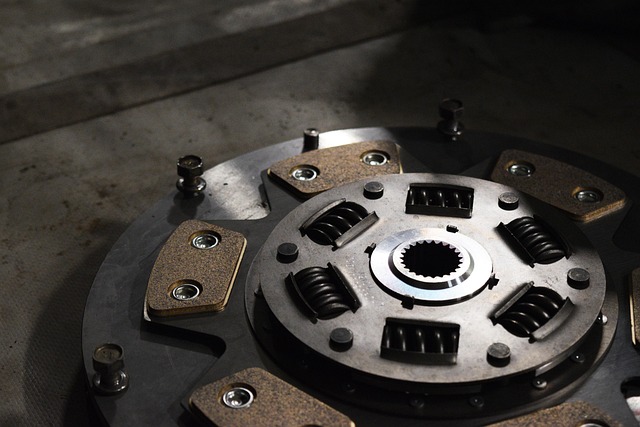

In the realm of precision collision repair, adhering to strict manufacturer specifications is paramount. Every detail, from precise measurements to specific material formulations, must be met to ensure quality and safety. This meticulous approach goes beyond mere aesthetics; it guarantees that vehicles return to their original structural integrity after repairs. For example, in bumper repair or frame straightening procedures, technicians utilize advanced equipment to achieve factory-like accuracy, ensuring the vehicle’s safety features function optimally.

The significance of strict adherence cannot be overstated, especially in cases of complex vehicle collision repair. Every component must be aligned perfectly to prevent future mechanical issues and maintain optimal performance. This rigorous standard not only protects drivers but also contributes to the overall reliability of the automobile industry, where precision is the cornerstone of safety and efficiency.

Precision collision repair, guided by a deep understanding of manufacturer specifications and enhanced by cutting-edge technology, ensures that vehicles return to their pre-accident condition. By strictly adhering to these specs, repair shops maintain quality, safety, and the vehicle’s original integrity. This approach not only protects consumers but also preserves the value and reliability of their cars, fostering trust in an industry often fraught with concerns about subpar work.